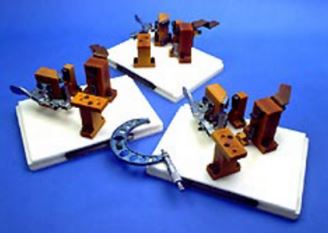

Fixtures

An expensive aircraft part is only as good as the fixture that holds it. That is why a significant sector of our business involves building an assortment of ultra precise heat treating, tooling, and machining fixtures that carry a long reputation for dependability.

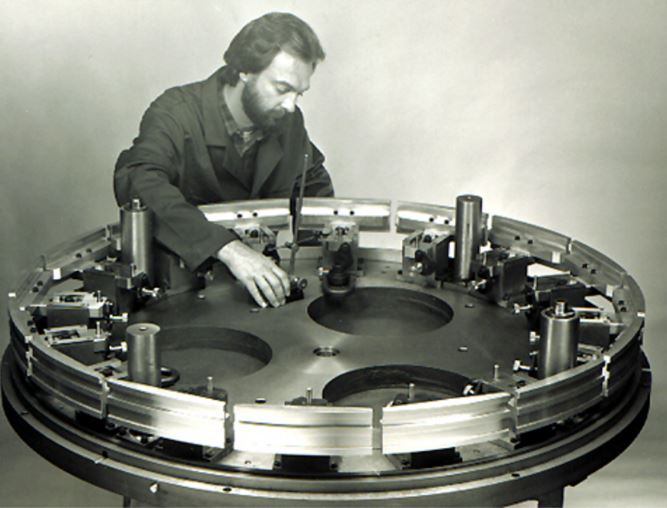

Overhauling large expensive fixtures is substantially more economical whenever possible. Our skilled craftsmen overhaul functionally obsolete fixtures, and completely restore them to new exacting tolerances.

CAPABILITIES

| SPECIALIZING IN: | ||

|---|---|---|

| Disks | Shafts | Hubs |

| Seals | Rings | Couplings |

| Fan Hubs | ||

| ADDITIONAL | ||

|---|---|---|

| Cases | Vanes | Housings |

| Assemblies | Shrouds | and More… |

- Blackhawk (Sikorsky)

- F100

- F119 (for the F22)

- GTF NEO Program

- J2

- JT8D

- JT9D

- PW2000

- PW4000

- TF33

- V2500

- F135

- PW6000

- GP7000

- Leap

- F135 – Joint Strike Fighter

- PW6000

- GP7000

- ATFI (PWC geared engine)

The Right Team – The Right Tools

With machining centers, the tool rotates, while the part is stationary. Generally, vertical machining is favored for precision, and horizontal machining for production, but these are generalizations. What’s important, is that the team at Budney has the tools and the talent on hand to deliver your next project, whatever your needs.