Engineering

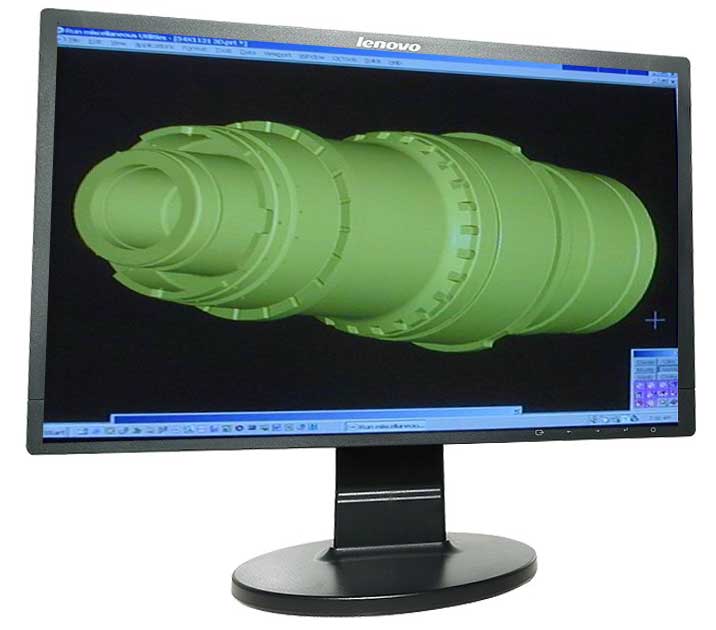

Using advanced technology to develop processes, the engineers at Budney Industries are experienced in a wide variety of materials, methods, configurations and specifications.

We regularly work with alloys of nickel, cobalt, titanium, hardened steel, magnesium and aluminum – forged, rolled, cast & pressed powdered metal.

Many of our parts are “Engineering Source Approved” – manufactured under tightly controlled conditions to guarantee many years of tough service.

As a job shop, Budney Industries has the flexibility to interact with our customer’s design engineers, implementing changes as they are made.

CAPABILITIES

| SPECIALIZING IN: | ||

|---|---|---|

| Disks | Shafts | Hubs |

| Seals | Rings | Couplings |

| Fan Hubs | ||

| ADDITIONAL | ||

|---|---|---|

| Cases | Vanes | Housings |

| Assemblies | Shrouds | and More… |

- Blackhawk (Sikorsky)

- F100

- F119 (for the F22)

- GTF NEO Program

- J2

- JT8D

- JT9D

- PW2000

- PW4000

- TF33

- V2500

- F135

- PW6000

- GP7000

- Leap

- F135 – Joint Strike Fighter

- PW6000

- GP7000

- ATFI (PWC geared engine)

Machining nickel alloy with ceramic inserts

Benefits of Working With Budney

- Unmatched Quality

- Commitment to Service

- Deep Industry Experience

- Ability to Meet Your Delivery Schedule

CONTACT US

Contact us today to discuss your next project

The team at Budney is eager to assist

CONTACT US