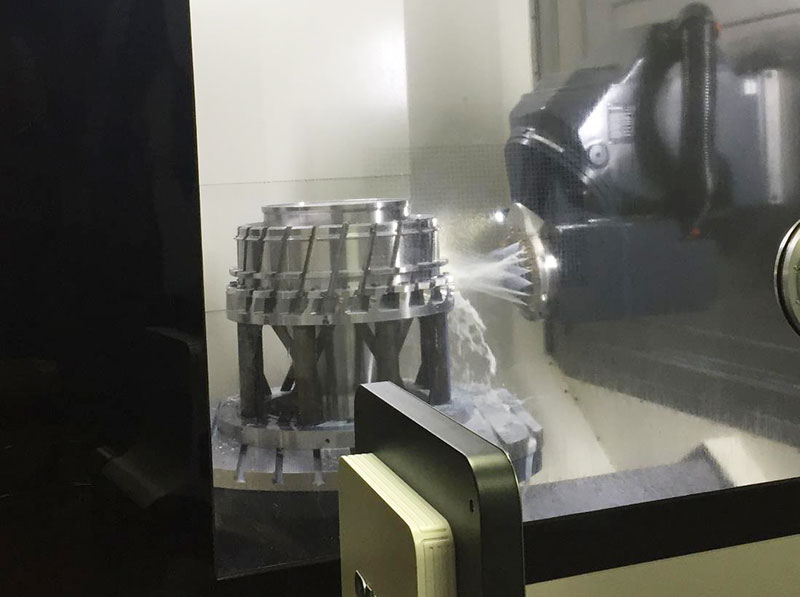

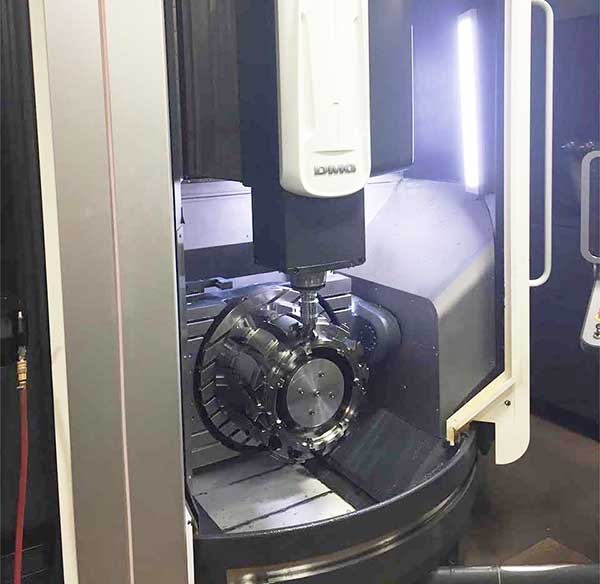

5 Axis Machining

Aerospace contractors find special interest in our 5 Axis machining capabilities which complement our turning department. Our multi-talented work force excels in the art of fabricating exotic alloys into exacting parts and assemblies with their comprehensive knowledge of these state of the art 5 Axis machining centers. A few of the benefits of 5 axis machining:

- Highest degree of accuracy

- Save time and money – less preparation (single machine setup)

- High quality finishes

- Ability to produce complex parts

CAPABILITIES

| SPECIALIZING IN: | ||

|---|---|---|

| Disks | Shafts | Hubs |

| Seals | Rings | Couplings |

| Fan Hubs | ||

| ADDITIONAL | ||

|---|---|---|

| Cases | Vanes | Housings |

| Assemblies | Shrouds | and More… |

- Blackhawk (Sikorsky)

- F100

- F119 (for the F22)

- GTF NEO Program

- J2

- JT8D

- JT9D

- PW2000

- PW4000

- TF33

- V2500

- F135

- PW6000

- GP7000

- Leap

- F135 – Joint Strike Fighter

- PW6000

- GP7000

- ATFI (PWC geared engine)

What is it?

5 axis machining gives us infinite options to create your part. In addition to the linear X, Y and axes the cutting tool has the additional A & B axes, which allows it approach your part from any angle. In the right hands incredibly complex geometries can be created with 5 axis machining. An added benefit is the ability to achieve these results with just one setup, which lowers your overall costs, thanks to lower tooling costs.

Widely used within a number of industries and applications including

- Aerospace

- Medical

- Automotive

- Prototyping